Abrasive Belt Joints

PFE Technologies supplies belts with various types of joints, all according to the stringent Klingspor standards. The type of joint you require depends on the work involved and the machine you are using. The following illustrations show the usual types of joint.

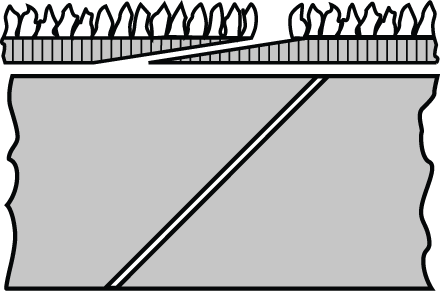

F1 Joint

Diagonal cut, glue overlapped.

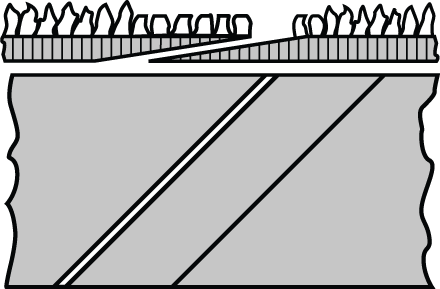

F2 Joint

Diagonal cut, glued overlapped. Grain tips are completely removed from the overlap to provide for a smoother running belt.

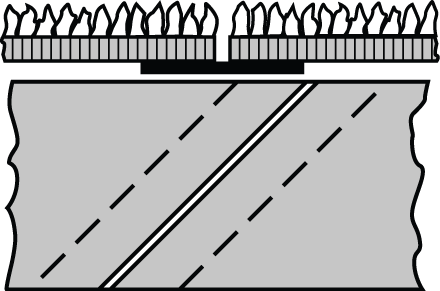

F4G Joint

Diagonal cut. Butt joint with cloth-reinforced foil backing. Also suitable for working on unsupported belts. For demanding requirements.

The Importance of Strong Joints

Abrasive belt joints are the weakest link of an abrasive belt – most belt failures or breakages will occur at the joint. This is why it’s important to choose the correct joint for your belt – and perhaps more importantly – to choose a supplier who can make very strong, durable belts with proper jointing methods and quality assurances.

PFE Technologies Pte Ltd provides the belt conversion and jointing services for Klingspor abrasives to the local clientele, and joints it Singapore to uphold the highest belt standards. With a team of highly skilled and experienced workers, and with more than 20 years of experience jointing and supplying belts, you can count on PFE Technologies for the top-quality belts to be used in the most demanding applications.

If you need specialized abrasive belt customizations, or if you have specific requirements, do get in touch with us. We’ll be happy to help.

Sources

The information and images in this page are extracted from the Klingspor Catalogue, provided by Klingspor AG.

A copy of this catalogue may be found here. The information is on page 38.

Text and images are copyright Klingspor AG, 2015.